How do I maintain my Flexofold Folding Propeller?

A Flexofold Propeller requires minimal upkeep.

Our folding propellers demand just the basics: cleaning and polishing. By removing fouling from the blades and maintaining your propeller, you ensure it keeps performing well. A key advantage of our folding propellers is their water-lubricated design, which means you don't need to worry about regular lubrication.

Follow our step-by-step guide further down this article, and lets start with the basics:

When to maintain?

We recommend cleaning and polishing the propeller as soon as you haul out the boat, as it's much easier to clean then. Alternatively, clean and polish the propeller before launching.

For boats that stay in the water all year without being hauled out for winter storage, we suggest doing a service check and cleaning the propeller if you notice it's not unfolding or folding as smoothly as usual.

What products should I avoid using?

People often inquire about what our folding propellers can withstand. Here's a general guideline:

- Avoid using mineral oils and gasoline on the propellers

- Our propellers are designed to withstand mild acids and bases

Heavy fouling

In areas with heavy fouling, you might consider using antifouling paint on the propeller. However, it's up to you whether or not to use this solution. The use of such products is not a compulsory part of our maintenance routine. If you decide to use antifouling paint, we don't recommend a specific product but suggest consulting with your local marine supply store.

However, be aware that antifouling paint should NOT be applied to the gearing, blade roots, or the blade socket in the hub, where the blades move during folding and unfolding.

Further down in this article, we'll explain which specific areas to avoid painting and why it's crucial not to apply paint there. We've seen cases where folding propellers couldn't open or close at all after being painted with antifouling paint in these areas.

Step 1 – Descale

First up, you need to descale the propeller. Always descale before polishing. Fouling on propellers and boats mainly consists of calcareous deposits, so descaling both the blades and the hub helps. It's easiest to remove the fouling if you start the descaling process as soon as the boat is hauled out of the water.

Product:

The descaling products suitable for folding propellers are the same as those used for descaling your coffee machine. Follow the instructions on the product and use the same dilution ratio as when descaling coffee machines.

NOTE: Steer clear of harsh chemicals, especially on our saildrive hubs, as they can damage the friction clutch.

- Remove the propeller from the sail drive or shaft

- Take off the anode (this should not be descaled)

- Disassemble the propeller

- Place the hub and blades in the descaling solution and leave for a maximum of 8 hours

Composite hubs can be descaled in the same way.

Step 2 – Cleaning

After descaling, the propeller must be cleaned. We recommend using fine steel wool, similar to what is used for cleaning pots and pans. Be careful not to confuse steel wool with steel scouring pads/sponges, as the latter are much more abrasive and will significantly damage the propeller's surface.

If using a material more abrasive than steel wool, take care not to unbalance the blades, as an abrasive material will wear down the surface. We'll cover this more in the polishing section.

A helpful tip is to clean the propeller as soon as the descaling is done, as it's much easier to scrub clean while it's still wet.

Step 3 – Lubrication

Our propellers are water-lubricated, eliminating the need to grease the moving parts. After cleaning the prop, it’s usually very dry, so grease can be applied, but only to specific parts. This is actually the only time you need to grease the prop.

Product:

We recommend using 'ProLan Protective Lanolin – heavy' spray.

Note: Use only in small amounts.

Parts that can be lubricated when mounting the propeller:

• Pins

• Pin holes

Avoid using grease in large quantities, as it will just be flung off when the propeller is in use, thereby ending up in the marine environment.

Sand and small shells can get stuck if you apply grease to other parts of the propeller. It’s similar to when you apply sunscreen on your hand and then press it into the sand—the sand sticks to your hand. That’s why we recommend avoiding grease (except for applying it to pins and pin holes) to prevent sand, debris etc. from getting trapped in the propeller, especially the gearing.

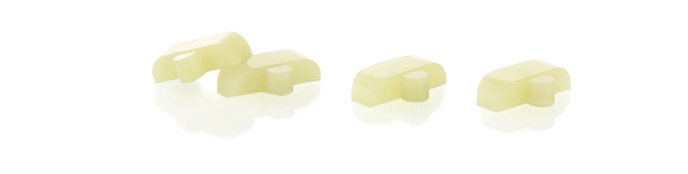

Step 4 – Check the Shock Absorbers

Ensure you perform routine maintenance checks on your propeller.

The shock absorbers ensure smoother opening of the propeller blades, protecting both the hub and the gearing.

Check if the shock absorbers still retain their original shape. If they do, there's no need to replace them.

Signs that the shock absorbers need replacing:

- They have visible cracks

- They've lost their original shape

- They show clear signs of marks or surface damage

Step 5 – Polishing

Once the propeller is descaled and cleaned, it needs to be polished.

We recommend using a brass polish and following the instructions on the product label. Although time-consuming, we advise polishing by hand to best preserve the propeller's original design and shape.

If you choose to use a polishing machine, we strongly recommend using a felt disc, as sandpaper will alter the surface. Sandpaper or other more abrasive materials could ultimately unbalance the propeller by wearing down the surface.

Creating an imbalance in the propeller can happen quickly – it doesn't take much.

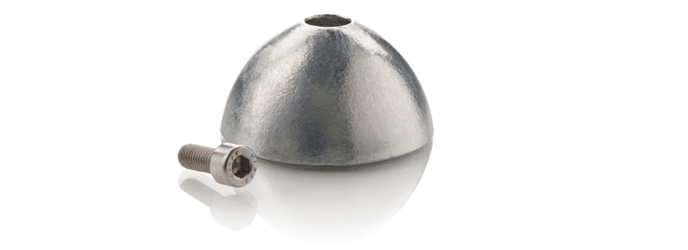

Step 6 – The Anode

The final step is a routine inspection of the anode. The anode protects your propeller from electrolysis. Learn more about what electrolysis is and how to protect your folding propeller against it here.

In that blog post, you will also see examples of anodes that have sailed the same amount of time but have vastly different shapes. Several factors influence how quickly the anodes wear down. Therefore, make sure to perform routine maintenance checks on the anode regularly, and not just when the boat is hauled out of the water. The anode can be replaced quickly and without much effort underwater, so if you're up for a dip, you can ensure the best conditions for your folding propeller

The anode should be replaced when:

- 50% of the anode is gone

- It has lost its original rounded shape

- The surface is no longer intact/the zinc has started to disappear

This anode has been in the water for only 3,5 weeks, but it has definitely done its job!

This anode has been in the water for only 3,5 weeks, but it has definitely done its job!

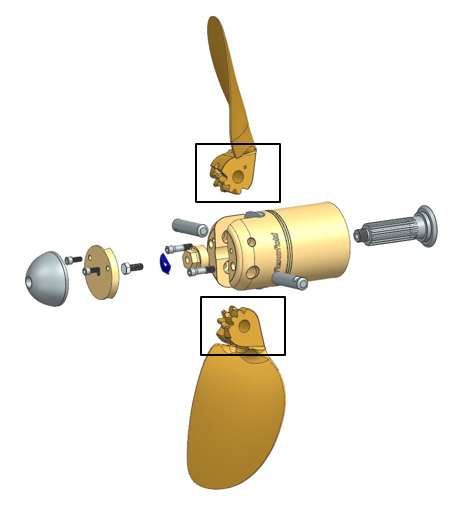

Antifouling Paint

When it comes to applying antifouling paint on a folding propeller, precision is key to ensuring optimal performance. As mentioned, we don't recommend a specific product, and it's up to the individual whether to use this product. We advise you to seek guidance from your local marine supply store, as there are various products on the market.

The blades should be able to move freely, folding and unfolding without any issues. Therefore, it's crucial to keep parts of the propeller free from antifouling paint to maintain its functionality.

In this section, we'll carefully describe the areas where you should refrain from applying antifouling paint to preserve the propeller's functionality.

NOTE: Some brands recommend sanding before applying antifouling paint. Be careful not to sand away too much of the surface, as this can cause an imbalance in the propeller. Read "Step 5 - Polishing"!

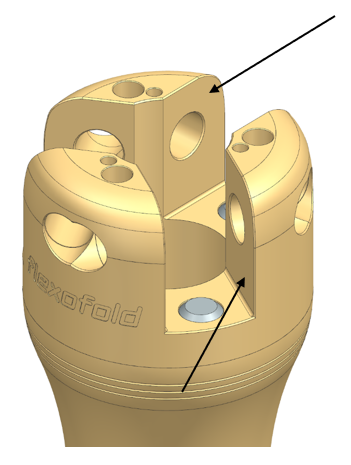

Gearing

Do not apply antifouling paint to the gearing. The gearing must be free of coating to ensure a smooth and efficient folding and unfolding mechanism. Applying antifouling paint to the gearing will prevent the blades from folding and unfolding properly.

The gearing on our folding propellers is made with precision, allowing you to experience a trouble-free folding mechanism. This ensures low drag when the propeller is folded under sail. If the folding mechanism is compromised due to antifouling paint, it could ultimately render the propeller non-functional. This means the blades might only open halfway, preventing you from fully utilizing the propeller's thrust when starting the engine.

Blade Root

Avoid applying antifouling paint to the root of the blades. The blade roots need to move freely when the propeller folds and unfolds. The blade roots must be free of coating to ensure a smooth and efficient opening and closing mechanism.

Blade Socket

In the blade socket, where the blade root is located when the propeller is assembled, antifouling paint should also be avoided. Here too, it's essential for the opening and closing function to operate smoothly.

Cover Plate

If the anode doesn’t have direct contact with the propeller, its effectiveness will be significantly reduced. Therefore, the cover plate should not be painted.

By regularly and properly maintaining your Flexofold Folding Propeller, you ensure it always performs at its best. This will also help maintain the exceptional longevity that our propellers are renowned for.